Providing complete business solutions

for our customers is

our success.

About us

We are a dynamic collective of founders and business owners, united by a shared vision to redefine the landscape of tool-making. Our collaborative venture brings together established companies from Germany, Switzerland, and China, leveraging our diverse expertise to offer unparalleled solutions in stamping and injection molds.

People

Our commitment to customer care is at the heart of everything we do. From the very beginning, our dedicated project managers work closely with you to understand your needs and guide you through each step of the process. But our service doesn’t stop at delivery. Once your tool is utilized across various factories around the world, we continue to support you with comprehensive Tooling Repair and Maintenance services. Our focus on Optimization ensures that your operations run smoothly and efficiently.

+000

Locations

With a strong foundation in precision engineering, our Swiss, German, and Chinese heritage guarantees that every product we create meets the highest standards of quality and accuracy. We specialize in various industries, including consumer goods and automotive, providing customized molds tailored to each unique requirement. Our capabilities extend to manufacturing parts, allowing us to offer comprehensive solutions that streamline production and enhance efficiency.

+4

Projects

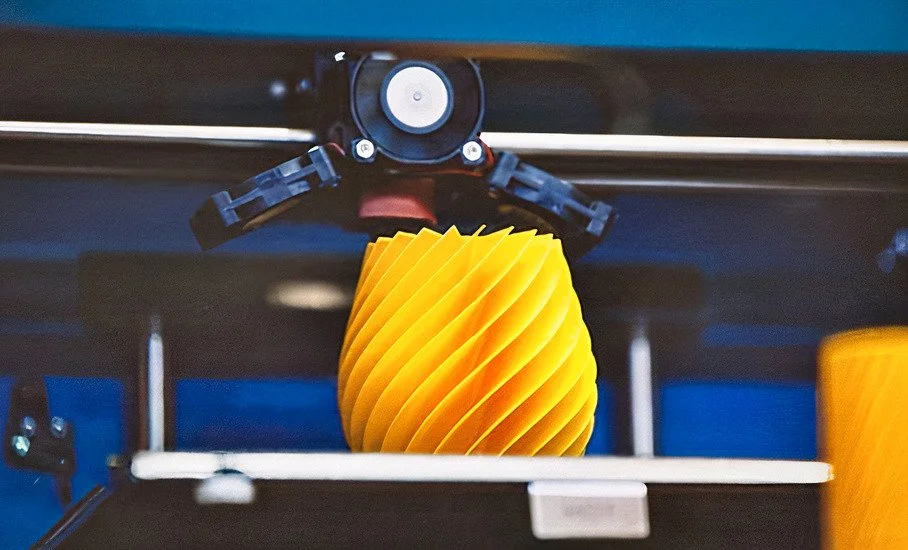

Our services encompass every aspect of the tooling lifecycle. From Tool Design and Prototyping to advanced 3D Printing, our team utilizes cutting-edge technology and software for thorough Analysis and development. We ensure that every tool we create not only meets your specifications but also optimizes performance and durability.

+00

Our Promise:

From Idea to Finished Product

We specialize in the development and manufacture of sophisticated, high-precision injection molds for the automotive, electrical, leisure, and packaging industries.

Reliability through In-House Development and Construction

Our commitment to excellent quality is supported by state-of-the-art machinery and a team of specialized personnel, ensuring flexibility and precision in every project.

Punctuality

We prioritize timely delivery, ensuring that your projects are completed on schedule.

Our Standards:

Experienced in the Electronics Industry

We have extensive experience in multi-component injection molds, including up to 3-K configurations.

Fully Networked CNC Structure

Our fully integrated CNC structure ensures precision and efficiency in production.

Operational Availability

We offer 24/7 running time capabilities to meet your production needs.

Why choose us

From Tool Design and Prototyping to 3D Printing and part manufacturing, we cover every aspect of the tooling lifecycle, providing a one-stop solution for all your needs.

High-Quality Standards

With a strong foundation in precision engineering, we adhere strictly to the highest industry standards at every stage of production. Our rigorous quality control processes ensure that we consistently deliver exceptional results, meeting and exceeding customer expectations.

Flexibility

Our approach provides unmatched flexibility, delivering fast, customized solutions designed to meet your unique needs and adapt quickly to changing circumstances. We prioritize efficiency while ensuring that every solution is tailored to your specific requirements, offering both speed and precision.

Price

We offer highly competitive pricing, made possible by our efficient production processes in China. By leveraging cost-effective manufacturing without compromising quality, we deliver excellent value for money, ensuring you receive premium products at a fraction of the usual cost.

Project Process

It is particularly important to us that you know from the outset what we offer you. For us, this includes not only the technical level but also service and cooperation

Customer inquiry

Send us your inquiry along with relevant data, such as 3D files.

Quotation preparation

We will review your requirements, assess their feasibility, obtain pricing from our suppliers, and prepare a quotation for you.

Order

Once all details are clarified, your order initiates our work, beginning with the construction of your tool.

Design

We optimize your component and design a high-quality tool concept to ensure efficient production.

Toolmaking

After you approve our design, we collaborate with our Chinese partners to begin building your tool. We will keep you updated with weekly project status reports.

Sampling T1

After the preliminary tool completion, we conduct tryouts by producing sample parts with the created mold for your evaluation. A measurement report will also be provided.

Ready for series production T2

Based on your feedback from the initial samples, we make adjustments and send you updated samples.

Acceptance and approval T3

If the revised parts meet your satisfaction, you will approve the tool. Otherwise, further tryouts will be conducted.

Transport

We handle the packaging and transport of your tools. You can track them by using a GPS tracker.

Aftersales

We are happy to coordinate any subsequent adjustments with our local partners and offer regular servicing of your machines.

We would like to be your partner for

Tooling and Prototyping

It all begins with an idea. Whether you're looking to launch a business or transform a hobby into something more, we are here to help.

Competitive Solutions

Starting your own business can be intimidating. Learn how to present yourself and your concepts with confidence.

High Speed Projects

We aim to help you reach your maximum potential, whether it's by building brand loyalty or expanding your business offerings.

Innovation and Precision

We continuously embrace cutting-edge technologies and methodologies to enhance our processes, ensuring that every product we deliver meets the highest standards of accuracy and quality.

As an international partner and system supplier, we consider ourselves a long-term, skilled ally to the industry. Our success lies in providing comprehensive business solutions for our customers. We specialize in managing complex projects in the plastics and steel sectors, covering everything from part design to the final product.